This application relies for priority on U.S. Provisional Patent Application Serial No. 60/237,489, entitled “Adjustable Apparatus and Kit for a Coupled Snowmobile Suspension,” filed on Oct. 4, 2000, the entirety of which is incorporated herein by reference.

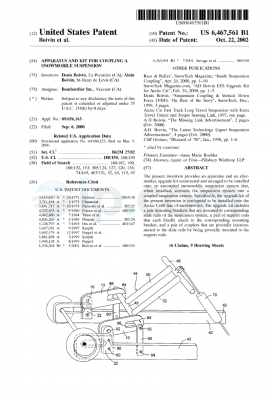

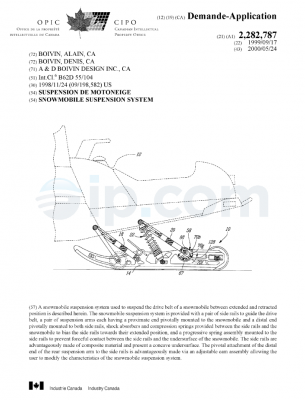

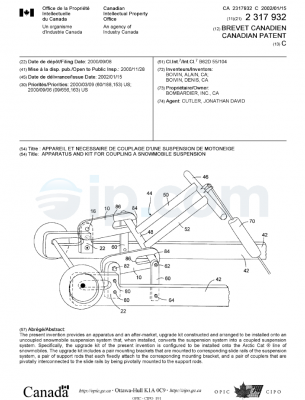

This invention relates to snowmobile suspension systems, and more particularly to coupled suspension systems, and even more particularly to an apparatus, in the form of an after-market upgrade kit, that permits, when installed, quick and easily accessible coupling adjustment.

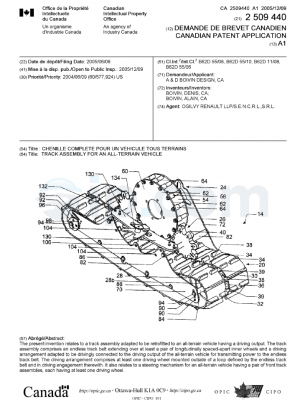

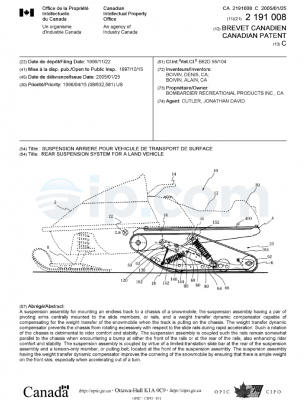

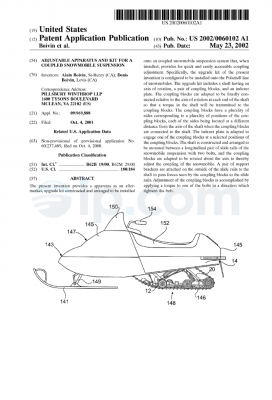

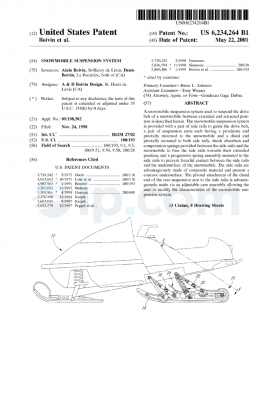

Tracked vehicles such as snowmobiles have rear suspension systems generally consisting of front and rear suspension arms pivotally mounted on shafts, which are rotatably connected to the frame of the snowmobile, and a slide frame, which comprises a pair of laterally spaced apart slide rails or longitudinal skids interconnected transversely on opposing lateral sides of the machine. The slide rails are in sliding contact with an endless belt which provides ice and snow surface contact and a friction drive for the snowmobile. In many current arrangements, front and rear suspension arms pivotally interconnect the chassis to the slide frame.

It is generally known in the art that independent movement of the front and rear suspension arms is less desirable than a suspension system in which the front and rear suspension arms are coupled. In an uncoupled suspension system, when the front suspension arm deflects as it contacts a bump, the independent rear suspension arm remains in its ride or fully extended position. This results in an angle of incidence between the slide rails and the bump. Unless the impact is so large that it compresses the rear suspension arm spring and shock absorber assembly, thereby flattening the angle of incidence, the slide rails will act as a ramp forcing the rear of the snowmobile upward. That is, with the slide rails angled in an upward incline due to the independent deflection of the front suspension arm, but not the rear suspension arm, the snowmobile will hop over the bump, imparting a secondary jolt which increases in intensity with the speed of the snowmobile. This secondary jolt also results in a loss of control and a reduction of the speed of the snowmobile.

On the other hand, a coupled suspension system is one in which, for example, the rear portion of the suspension system reacts (i.e., is coupled) to the compression experienced by the front portion of the suspension system as the snowmobile passes over a bump in the terrain. In effect, the bump is “communicated” to the rear portion of the suspension, causing the rear portion to be pulled upward toward the chassis before the rear portion actually reaches the bump. This reduces the angle of incidence between the slide rail and the bump, which thereby reduces the secondary jolt experienced by the rider. As a result, a coupled suspension system provides for an improved ride because the coupled suspension is better suited to adjust to varying terrain conditions.

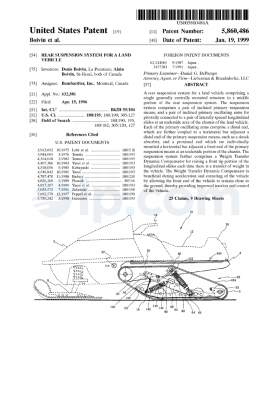

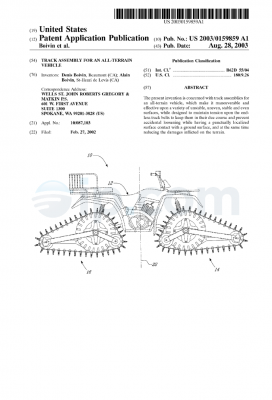

Manufacturers have developed a variety of ways to provide coupled suspension systems, which typically involve restricting the amount of longitudinal movement of the rear suspension arm. Such systems are shown in U.S. Pat. Nos. 5,881,834, 5,692,579, 5,667,031, and 5,944,134, which are incorporated herein by reference.

The suspension system disclosed in Polaris’ U.S. Pat. No. 5,692,579 (“’579”) patent is shown in FIGS. 1-4 where FIG. 1 shows the overall suspension system removed from the snowmobile, and FIGS. 2-4 show the design approach used to couple the suspension system. As disclosed in the ‘579 patent and depicted in FIGS. 2 and 4, the linkage of the rear suspension arm 20 with the lower pivot arm 26 permits the front of the slide rails 10 to rise substantially independently of the rear portion of slide rails. During this independent movement of the front portion of the suspension, the lower pivot arm 26 pivots from the rearward position shown in solid lines in FIG. 2 to the forward position depicted in broken lines. At the point which the front surface 27 of the lower pivot arm 26 engages the front adjuster block 30, further independent upward movement of the front end of the suspension is prevented. That is, further upward movement of the front of the slide rails 10 is mechanically linked through the adjuster block 30 to the rear suspension arm 20, causing upward movement of the rear of the suspension (the rate of upward movement of the rear of the suspension may or may not be equal to the rate of movement of the front of the suspension, depending on the specific geometric configuration of the system).

The degree of independent movement afforded to the front of the suspension rails 10 is dependent on the distance between the rear stop 32 and the front adjuster block 30 in comparison to the width of the lower pivot arm 26. The rear surface 31 of the front adjuster block 30 thus provides a limit on the relative forward movement of the lower end of the suspension arm 20 with respect to the slide rail 10.

The Polaris® system of the ‘579 patent further provides variability to the position of this limit, thereby giving the rider some control over the performance characteristics of the suspension. This variability is provided by using rectangular adjuster block 30, which has four surfaces that are each positioned at varying distances from the block’s central mounting point, as indicated by distances “d1” through “d4” in FIG. 4. By rotating the block to select one of the surfaces, the position of the limit with respect to the lower end of the suspension arm 20 can be controlled.

However, with the above Polaris® system, it is difficult for the rider to make a desired adjustment to the adjuster block 30, especially when the rider is in the field. To make an adjustment, the rider must first loosen the central mounting point (a bolt). Then, the rider must manage to rotate adjuster block 30, either with his fingers or with the aid of another tool, to the desired location, and then retighten the central mounting point. The rider must then repeat these steps for the adjuster block on the opposite side of the slide rail. Considering that the rider may wish to make such adjustments while in the field, where he/she would encounter other obstacles, such as deep snow, cold weather, and generally unfavorable conditions for handling tools and equipment, it is apparent that making such adjustments to the adjustable block 30 in order to compensate for differing terrain conditions is difficult with the above Polaris® system.

It is therefore the object of this invention to provide an apparatus, in the form of an after-market upgrade kit, for installation onto a coupled snowmobile suspension system of the kind described in U.S. Pat. No. 5,692,579 that, when installed, allows for a quick and easy adjustment of the front to rear coupling.

It is further an object of the present invention to provide an apparatus, in the form of an after-market upgrade kit, specifically configured to be installed onto the Polaris® line of snowmobiles.

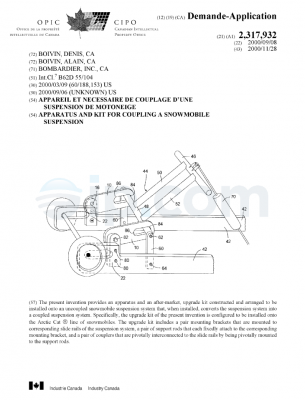

It is the object of the present invention, therefore, to provide an apparatus and an after-market upgrade kit constructed and arranged to be installed onto a coupled snowmobile suspension. The upgrade kit includes a shaft having an axis of rotation, a pair of coupling blocks, and an indexer plate. The coupling blocks are adapted to be fixedly connected relative to the axis of rotation at each end of the shaft so that a torque in the shaft will be transmitted to the coupling blocks. The coupling blocks have a plurality of sides corresponding to a plurality of positions of the coupling blocks, each of the sides being located at a different distance from the axis of the shaft when the coupling blocks are connected to the shaft. The indexer plate is adapted to engage one of the coupling blocks at a selected positions of the coupling blocks. The shaft is constructed and arranged to be mounted between a longitudinal pair of slide rails of the snowmobile suspension, and the coupling blocks are adapted to be rotated about the axis to thereby adjust the coupling of the snowmobile.

Other objects and advantages of the present invention will be realized in accordance with the following detailed description, appended drawings, and claims.

The various embodiments of the present invention are shown throughout the drawings, in which:

FIG. 1 is a perspective view of a coupled snowmobile suspension of the prior art;

FIG. 2 is a plan view of the snowmobile suspension illustrated in FIG. 1, also showing the coupling apparatus;

FIG. 3 is an enlarged view of a portion of the coupling apparatus shown in FIG. 2;

FIG. 4 is an enlarged view of the coupling block depicted in FIGS. 2 and 3, which are known in the art;

FIG. 5 is a perspective view of the preferred embodiment of the apparatus of the present invention, showing the assembly thereof before attachment to the snowmobile suspension;

FIG. 6 is a plan view of the shaft of the upgrade kit of the preferred embodiment;

FIG. 6B is a section view of the rectangular portions of the main shaft shown in FIG. 6;

FIG. 6C is a plan view of a second embodiment of the main shaft, where the coupling blocks are integrally formed with the main shaft;

FIG. 7 is a plan view of a coupler block of the upgrade kit of the preferred embodiment;

FIG. 8 is a side view of a coupler block of the upgrade kit of the preferred embodiment;

FIG. 9 is the plan view of the coupler block shown in FIG. 7, showing dimensional attributes;

FIG. 10 is a perspective view of a coupling block having mounted thereto a ball spring plunger, which is the preferred embodiment of a protrusion of the upgrade kit;

FIG. 11 is a side view of the coupling block shown in FIG. 10;

FIG. 12 is a side view of a coupling block having mounted thereto a second embodiment of a protrusion;

FIG. 13 is a side view of a coupling block having mounted thereto a third embodiment of a protrusion;

FIG. 13B is a perspective, exploded view of a second embodiment of the indexer plate and coupling blocks, where the indexer plate has mounted thereto any of the protrusions of FIGS. 11, 12, 13 and the coupling block includes a plurality of depressions;

FIG. 14 is a plan view of the indexer plate of the upgrade kit of the preferred embodiment;

FIG. 15 is a plan view of a support plate of the upgrade kit of the preferred embodiment;

FIG. 16 is a plan view of a Polaris® XTRA-10 snowmobile suspension system without the upgrade kit installed;

FIG. 17 is an enlarged view of the coupled portion of the snowmobile suspension illustrated in FIG. 16;

FIG. 18 is a plan view of a portion of the suspension system of FIG. 16 with the upgrade kit installed;

FIG. 19 is a top view of the upgrade kit installed onto the Polaris® XTRA-10 snowmobile suspension system shown in FIG. 16;

FIG. 20 is a depiction of the position of the lower arm engaged with a coupler block in two different positions of the coupler block; and

FIG. 21 is a snowmobile including the upgrade kit of the present invention.

Referring now more particularly to the Figures, wherein like reference numbers are used for like components where applicable, the apparatus of the present invention, which is also referred to as an upgrade kit, is generally indicated at 40 and is illustrated in FIG. 5. Generally, the upgrade kit 40 is constructed and arranged to be installed onto an adjustably-coupled snowmobile suspension system, so that, when installed, the adjustment of the coupling may be made more rapidly and easily than adjustment systems known in the prior art. More specifically, the upgrade kit 40 is configured to be assembled onto the Polaris® line of snowmobiles that are originally manufactured with adjustably-coupled suspension systems, as described above with reference to FIGS. 1-4.

Referring to the FIG. 5, the upgrade kit 40 comprises, among other components, a shaft 42, two adjustable coupling blocks 46, 48, an indexer plate 50, two bolts 54, 58, and two plate brackets 62, 66. FIG. 5 shows the upgrade kit 40 as an assembly, but not installed onto the suspension system, and FIGS. 6-15 show each component separately. The adjustable coupling blocks 46, 48 are hereinafter referred to as the coupling blocks 46, 48, and shaft 42 is also referred to as the main shaft 42.

As seen in FIGS. 5, 6, and 6B, the main shaft 42 comprises a cylindrical portion 68 and two rectangular portions 70, 72 mounted at each end of the main shaft 42. The axis of the main shaft 42 is designated as reference numeral 74 in FIG. 6B. The corners of the rectangular portions 70, 72 preferably include longitudinal chamfers 76 (see FIGS. 6 and 6B) that extend a length L3 from the end of the main shaft 42, which are configured to accommodate the coupling blocks 46, 48, described below. Each end of the main shaft 42 has a threaded bore 78 formed to a depth of length L3 therein. The threaded bores 78 accommodate the bolts 54 and 58 in order to mount the upgrade kit 40 to the snowmobile suspension.

The rectangular portions 70, 72 and cylindrical portion 68 of the main shaft are preferably integrally formed with the cylindrical portion 68 of the main shaft 42. The main shaft 42 is preferably machined from a single piece of machine stock. Of course, the main shaft 42 may be formed by other manufacturing techniques, such as by a casting. Alternatively, the rectangular portions 70, 72 may be separately formed and welded or otherwise connected to the cylindrical portion 68 to form main shaft 42. Also, the entire main shaft 42 may be rectangular, and the cylindrical portion 68 need not be present. In the preferred embodiment, the main shaft 42 is made of aluminum. However, it is contemplated that any other suitable material may be used, as long as the material selected is sufficiently strong and rigid.

Each coupling block 46, 48, shown separately in FIG. 7, is a generally rectangularly-shaped, rigid structure and includes a generally rectangular bore 80. The dimensions of the rectangular bore 80 are substantially the same as the dimensions of the rectangular portions 70, 72 of the main shaft 42, such that the rectangular portions 70, 72 matingly engage the bore 80. The rectangular portions 70, 72, therefore, transmit torque from the main shaft 42 to the two adjuster coupling blocks 46, 48 during rotation of the main shaft 42. The axis 74 of main shaft 42, when the main shaft 42 has been inserted into the coupling blocks 46, 48, is coincident with the centers of the rectangular bores 80. The corners of the rectangular bore 80 are, preferably, fillet radiused in a size to prevent interference with the chamfers 76 of the rectangular portions 70, 72. Also, the outside corners of each coupling block 46, 48 are preferably rounded with radii R1, R2, R3, and R4 to facilitate rotation of the blocks.

Although in the preferred embodiment, the adjuster coupling blocks 46, 48 are separate structures from the main shaft 42, it is also contemplated that the adjuster coupling blocks 46, 48 may be integrally formed with the main shaft 42 (see FIG. 6C). That is, the main shaft 42 may comprise coupler blocks 46, 48 integrally formed at each end of the main shaft. In such a case, the rectangular portions 70, 72 for transmitting torque to the coupling blocks are not required.

Whether integrally formed or as a separate structure, each coupler block 46, 48 in the preferred embodiment includes a plurality of sides corresponding to a plurality of positions of the coupling blocks. In the preferred embodiment, the coupling blocks 46, 48 include four sides 84, 85, 86, 87 that are each located at a different distance from the axis 74 when the coupling blocks are connected to the main shaft 42. As shown in FIG. 9 for clarity, each side 84, 85, 86, and 87 is located a distance “d5,” “d6,” “d7,” and “d8,” respectively, from the center rectangular bore 80 (or, equivalently, the axis 74 of the main shaft 42). Adjustment of the coupling system after the upgrade kit 40 is installed onto the snowmobile suspension system is accomplished by rotating the coupling blocks 46, 48 so that the desired side is selected for use (i.e., to engage surface 27 of lower pivot arm 26, shown in FIG. 3), which is discussed in detail below.

In the preferred embodiment where the coupling blocks are separate structures from the main shaft, the adjuster blocks 46, 48 preferably are made of ultra high molecular weight (UHMW) plastic, which is chosen for its light weight but high strength, rigidity, and superior wear characteristics. However, it will be understood by those skilled in the art that other suitable materials could also be used, such as a steel alloy. If the coupling blocks are integrally formed with the main shaft 42, then, of course, the coupling block material would be the same as the main shaft material.

In the preferred embodiment, at least one of the coupling blocks 46, 48 includes a cylindrical bore 82 formed therethrough, and a ball spring plunger 90 is inserted therein, as shown in FIGS. 10 and 11. The ball spring plunger 90 acts as an index stopping “pointer” or protrusion for indexing the coupling blocks 46, 48 at a selected position in conjunction with indexer plate 50, which is described below. The ball spring plunger 90 is of the conventional type, and generally includes a protrusion or ball 96 resiliently disposed, by a spring 97, against an interior edge of a flange stop 94. The spring 97 is disposed within a cylindrical chamber defined by cylindrical walls 92, the diameter of which is slightly larger than the rectangular bore 80 so that the ball spring plunger 90 interferingly fits within bore 80.

Although a ball spring plunger 90 is used in the preferred embodiment, it will be understood by those skilled in the art that other mechanisms can also be used to perform indexing of coupling blocks 46, 48, such as, for example, a resilient cantilever spring 98 formed with a protrusion or ball 99, shown in FIG. 12, or a bevel spring 100 formed with a protrusion or ball 101, as shown in FIG. 13.

Indexer plate 50, shown separately in FIG. 14, has a through-hole 106 formed therethrough at one end and a through-hole 108 formed therethrough at its other end. Through-hole 108 is located approximately centrally of a generally circular portion 110 on the indexer plate 50. Four equally spaced-apart through bores 112, 114, 116, 118 are formed toward the periphery of the circular portion 110 and surround the through-hole 108. In the preferred embodiment, all of the holes are located at the same radial distance from the center of the through-hole 108. When the upgrade kit is installed onto the snowmobile, the through-hole 108 receives the bolt 54 for positioning the indexer plate 50 relative to the coupling blocks 46, 48 (the bolt 54, along with the bolt 58, also pivotally mounts the main shaft 42 to the slide rails 10), and one of the holes (i.e., either bore 112, 114, 116, or 118) is aligned with and engages the ball spring plunger 90 to establish a fixed position for the coupling blocks 46, 48. Through-holes 112, 114, 116, and 118 may also be depressions in the indexer plate with a depth sufficient to engage the protrusion or ball 96 of the ball spring plunger 90. The other end of indexer plate 50 is bolted, via the through-hole 106, to the slide rail 10 of the snowmobile to thereby fixedly define the position of the four holes 112, 114, 116, 118 with respect to the coupling blocks 46, 48. The distance between the center of the holes 106 and 108 is designated as L11. The indexer plate 50 is preferably made of brass having a thickness of 0.074 inches. However, any other suitable material with an appropriate thickness could also be used.

Although in the preferred embodiment a protrusion is mounted to one of the coupling blocks for engagement with a depression (or hole) of the indexer plate, it is contemplated that the indexer plate 50, rather than the coupling blocks 46, 48, may include the protrusions. That is, as shown in FIG. 13B, the ball spring plunger 90 may be mounted to indexer plate 50 for engagement with a plurality of depressions or bores 109 formed in one of the coupling blocks (see FIG. 13B).

Each plate bracket 62, 66, shown separately in FIG. 15, defines two through-holes 122, 124 formed therethrough at each end. The size and proximity of the through-holes 122, 124 correspond with the through-holes 106, 108 of the indexer plate 50. Thus, the distance, L12, between the through-holes 122 and 124 is substantially the same as the distance L11. The through-hole 124 of the plate bracket 62 receives the bolt 54, which also is received by the through-hole 108 of the indexer plate 50, and the through-hole 124 of the plate bracket 66 receives the bolt 58, as shown in the assembly drawing of FIG. 5. The through-hole 122 and the through-hole 106 receives another bolt 130 (see FIG. 19), thus fixedly mounting both the plate bracket 62 and the indexer plate 50 to the slide rail 10 (discussed below). The plate bracket 66 of the opposite side of the snowmobile is likewise fixed to the slide rail 10, but without an indexer plate. The plate brackets 62, 66 provide support between the coupling blocks 46, 48 and the slide rail 10. That is, the brackets 62, 66 pass forces applied to the coupler system (when, for example, the lower arm 62 is urged against coupling blocks 46, 48) to the slide rails 10, which are made of aluminum. Because they are designed to carry stress, the plate brackets 62, 66 are preferably made from a {fraction (3/16)}″ brass plate. However, it will be understood to those skilled in the art that the thickness or material used is not limited solely to brass, and that other materials and/or thicknesses can be used as long as the combination selected is sufficiently strong and rigid.

Referring now to FIGS. 16-20, the components of the upgrade kit 40 described above are constructed and arranged to be assembled and attached to the slide rails 10 of a coupled snowmobile suspension system. More specifically, the upgrade kit 40 is configured to be assembled onto a Polaris® snowmobile suspension system of the type which is generally depicted, without the upgrade kit 40 attached, in FIGS. 1-4. Even more specifically, the upgrade kit 40 is configured to be assembled onto the Polaris® XTRA-10 snowmobile suspension system, which is depicted in FIGS. 16 and 17. As seen in FIGS. 16 and 17 of the XTRA-10 model, the coupler block 30, the rear stop 32, and the lower pivot arm 26, are slightly modified from the Polaris® model shown in FIGS. 1-4. The differences, however, are not substantial, so the same reference numerals are used for equivalent elements.

Français

Français