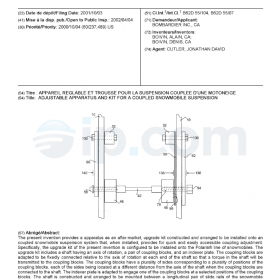

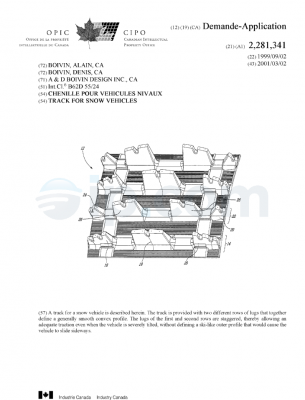

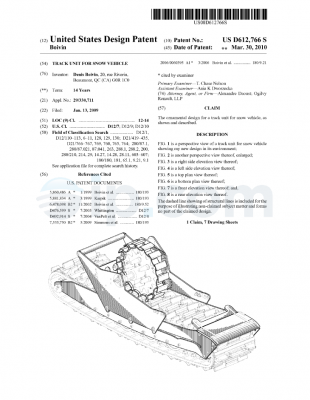

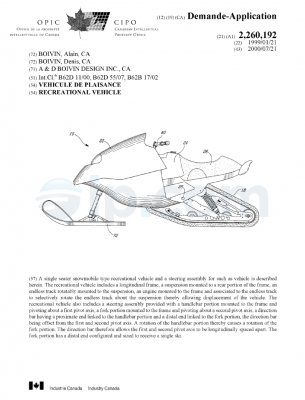

CA 02358154 2001-10-03

may be integrally formed with the main shaft 42 (see Fig. 6C). That is, the

main shaft 42 would

comprise coupler blocks 46, 48 integrally formed at each end of the main

shaft. In such case, the

rectangular portions 70, 72 for transmitting torque to the coupling blocks

would not be required.

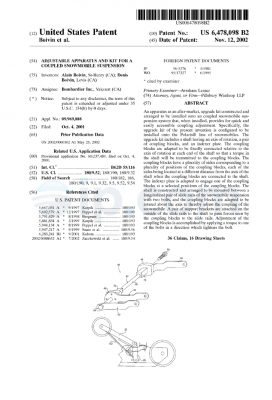

Whether integrally formed or as a separate structure, each coupler block 46,

48 in the

preferred embodiment includes a plurality of sides corresponding to a

plurality of positions of the

coupling blocks. In the preferred embodiment, the coupling blocks 46, 48

include four sides 84, 85,

86, 87 that are each located at a different distance from the axis 74 when the

coupling blocks are

connected to the main shaft 42. As shown in Fig. 9 for clarity, each side 84,

85, 86, and 87 is

located a distance « d5 », « d6 », « d7 », and « d8 », respectively, from the center

rectangular bore 80 (or,

equivalently, the axis 74 of the main shaft 42). Adjustment of the coupling

system after the upgrade

kit 40 is installed onto the snowmobile suspension system is accomplished by

rotating the coupling

blocks 46, 48 so that the desired side is selected for use (i.e., to engage

surface 27 of lower pivot

arm 26, shown in Fig. 3), which is discussed in detail below.

In the preferred embodiment where the coupling blocks are separate structures

from the

main shaft, the adjuster blocks 46, 48 are made of ultra high molecular weight

(UHMW) plastic,

which is chosen for its light weight but high strength, rigidity, and superior

wear characteristics.

However, it will be understood to those skilled in the art that other suitable

materials could also be

used, such as steel alloy. If the coupling blocks are integrally formed with

the main shaft 42, then,

of course, the coupling block material would be the same as the main shaft

material.

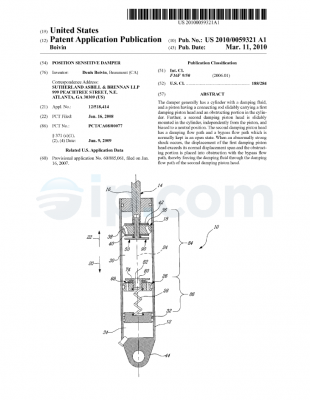

In the preferred embodiment, at least one of the coupling blocks 46, 48

includes a cylindrical

bore 82 formed therethrough, and a ball spring plunger 90 is inserted therein,

as shown in Figs. 10

and 11. The ball spring plunger 90 acts as an index stopping « pointer » or

protrusion for indexing the

coupling blocks 46, 48 at a selected position in conjunction with indexer

plate 50, which will be

9

CA 02358154 2001-10-03

described below. The ball spring plunger 90 is of the conventional type, and

generally includes a

protrusion or ball 96 resiliently disposed, by a spring 97, against an

interior edge of flange stop 94.

The spring 97 is disposed within a cylindrical chamber defined by cylindrical

walls 92, the diameter

of which is slightly larger than the rectangular bore 80 so that the ball

spring plunger 90

interferingly fits within bore 80.

Although a ball spring plunger 90 is used in the preferred embodiment, it will

be understood

by those skilled in the art that other mechanisms can also be used to perform

indexing of coupling

blocks 46, 48, such as, for example, a resilient cantilever spring 98 formed

with a protrusion or ball

99, shown in Fig. 12, or a bevel spring 100 formed with a protrusion or ball

101, as shown in Fig.

13.

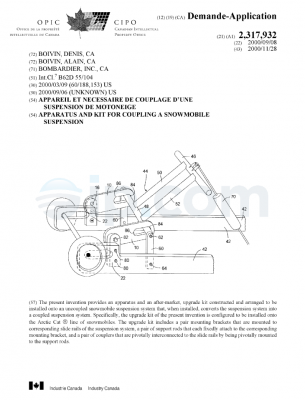

Indexer plate 50, shown separately in Fig. 14, has a through-hole 106 formed

therethrough at

one end and a through-hole 108 formed therethrough at its other end, which is

also located

approximately centrally of a generally circular portion 110 of indexer plate

50. Four equally

spaced-apart through bores 112, 114, 116, 118 are formed toward the periphery

of circular portion

110 in surrounding location of through-hole 108, and all the holes are located

at the same radial

distance from the center of through-hole 108. When the upgrade kit is

installed onto the

snowmobile, through-hole 108 receives bolt 54 for positioning the indexer

plate 50 relative to the

coupling blocks (bolt 54, along with bolt 58, also pivotally mounts the main

shaft 42 to the slide

rai1s10), and one of the holes (i.e., either bore 112, 114, 116, or 118) is

aligned and engaged with the

ball spring plunger 90 to establish a position of the coupling blocks 46, 48.

Through-holes 112,

114, 116, and 118 may also be depressions in the indexer plate of sufficient

size to sufficiently

engage the protrusion or ball 96 of the ball spring plunger 90. The other end

of indexer plate 50 is

bolted via through-hole 106 to the slide rail 10 of the snowmobile to thereby

fixedly define the

CA 02358154 2001-10-03

position of the four holes 112, 114, 116, 118 with respect to the coupling

blocks 46, 48. The

distance between the center of holes 106 and 108 is designated as L11. The

indexer plate 50 is

preferably made of brass plate having a thickness of 0.074 inches. However,

any other suitable

material and appropriate thickness could also be used.

Although in the preferred embodiment a protrusion is mounted to one of the

coupling blocks

for engagement with a depression (or hole) of the indexer plate, it is

contemplated that the indexer

plate 50, rather than the coupling blocks 46, 48, may mount the protrusions.

That is, as shown in

Fig. 13B, the ball spring plunger 90 may be mounted to indexer plate 50 for

engagement with a

plurality of depressions or bores 109 formed in one of the coupling blocks

(see Fig. 13B).

Each plate bracket 62, 66, shown separately in Fig. 15, defines two through-

holes 122, 124

formed therethrough at each end therein. The size and proximity of the through-

holes 122, 124

correspond with the through-holes 106, 108 of indexer plate 50. Thus, the

distance, L12, between

through-holes 122 and 124 is substantially the same as the distance L11.

Through-hole 124 of plate

bracket 62 receives bolt 54, which also is received by through-hole 108 of

indexer plate 50, and

through-hole 124 of plate bracket 66 receives bolt 58, as shown in the

assembly drawing of Fig. 5.

Through-hole 122 and through-hole 106 receives another bolt 130 (see Fig. 19),

thus fixedly

mounting both the plate bracket 62 and the indexer plate to the slide rail 10

(discussed below). Plate

bracket 66 of the opposite side of the snowmobile is likewise fixed to the

slide rail, but without an

indexer plate. The plate brackets 62, 66 provide support between the coupling

blocks 46, 48 and the

slide rail 10. That is, the brackets 62, 66 pass forces seen by the coupler

system (when, for example,

the lower arm 62 is urged against coupling blocks 46, 48) to the slide rails,

which are made of

aluminum. Because they are designed to carry stress, the plate brackets 62, 66

are preferably made

of 3/16″ brass plate. However, it will be understood to those skilled in the

art that the thickness or

11

CA 02358154 2001-10-03

material used is not intended to be limiting, and that other materials and/or

thicknesses can be used

as long as the combination selected is sufficiently strong and rigid.

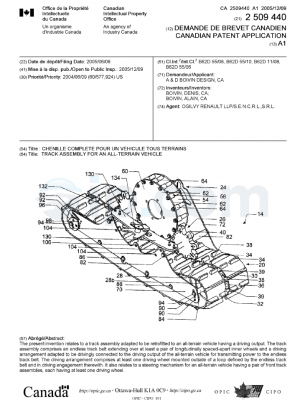

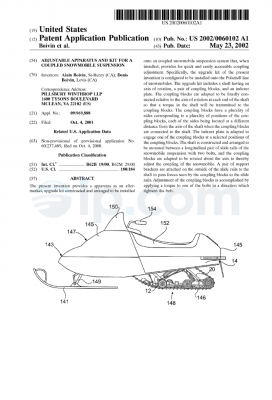

Refernng now to Figs. 16-20, the components of the upgrade kit 40 described

above are

constructed and arranged to be assembled and attached to the slide rails 10 of

a coupled snowmobile

suspension system. More specifically, upgrade kit 40 is configured to be

assembled onto a Polaris~

snowmobile suspension system of the type which is generally depicted, without

the upgrade kit 40

attached, in Figs. 1-4. Even more specifically, the upgrade kit 40 is

configured to be assembled

onto the Polaris~ XTRA-10 snowmobile suspension system, which is depicted in

Figs. 16 and 17.

As seen in Figs. 16 and 17 of the XTRA-10 model, the coupler block 30, rear

stop 32, lower pivot

arm 26, are slightly modified from the Polaris~ model shown in Figs. 1-4. The

differences,

however, are not substantial, so the same reference numerals are used for

equivalent elements.

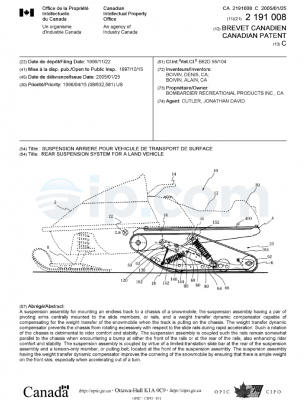

Generally, the suspension system of the Polaris~ snowmobile includes a slide

frame 13,

which comprises a pair of laterally spaced apart slide rails 10 or

longitudinal skids interconnected

transversely on opposing lateral sides of the machine. The slide frame 13 is

interconnected to the

snowmobile chassis 14 by a front and rear suspension arm, 12 and 20,

respectively. As more clearly

seen in Fig. 17, each coupling block 30 is mounted to the slide rails 10 with

bolts 126, and each rear

stop 32 is mounted to the slide rails 10 with bolts 128. As discussed above

and described in the

‘579 patent, the lower pivot arm 26 can rotate within the limits defined by

rear surface 31 of the

front adjuster block 30 and rear stop 32. The remainder of the suspension

system is known in the art

and described in the ‘579 patent, and therefore need not be described in

detail.

Referring now to Figs. 18 and 19, the attachment of upgrade kit 40 to the

Polaris~

suspension system will now be described. First, after raising and supporting

the suspension off the

ground, the bolts 126 and 128, which mount adjuster blocks 30 and rear stop

32, are removed. The

12

CA 02358154 2001-10-03

adjuster blocks 30 are then removed from the slide rails 10. Then, after

mounting the coupling

blocks 46, 48 of the upgrade kit 40 to the rectangular portions 70, 72 of main

shaft 42, the assembly

is installed so that coupling blocks 46, 48 replace the original blocks 30.

The main shaft assembly

(i.e., main shaft 42 and blocks 46, 48) is disposed on the inner side of the

slide rails 10 (see Fig. 19).

The indexer plate 50 is then inserted between adjuster block 48 (i.e., the

block that contains

the ball spring plunger 90) and a slide rail 10 on one side of the snowmobile

suspension. Through-

hole 108 of indexer plate 50 is aligned with threaded hole 72 of main shaft

42, and through-hole 106

is aligned with the mounting position of rear stop 32. The two plate brackets

62, 66 are then

installed on the outside of the slide rails 10, with through-holes 124, 122 of

each plate bracket

aligned with the threaded holes of the main shaft 42 and the m~unting

positions of each rear stop 32.

Bolts 54 and 58 are then put in place, but not fully tightened, in order to

retain the main shaft 42, the

indexer plate 50, and the plate brackets 62, 66. The original rear stop 32

mounting bolts 128 are

replaced with longer bolts 130 (preferably 1 1/2 x 318 NC bolts with a nylon

nut) and the rear stops

32 are rebolted, joining together the indexer plate 50, the slide rail 10, and

the plate brackets 62, 66.

Bolts 54 and 58 are then tightened for complete installation of the upgrade

kit 40. Preferably, a

torque of 400 in-lb is applied to bolt 54. If a limiter strap 132 is used in

the suspension system, it is

disposed below the main shaft 42, as shown in Fig. 18. Also, bolts 54 and 58

are preferably not

threaded over the entire length of the bolt. Rather, the portion of the bolts

extending beyond the

coupling blocks 46, 48 after installation have smooth surfaces for

rotationally sliding contact with

the indexer plate, slide rails, and support plates.

A top view of the installed upgrade kit 40 is shown in Fig. 19. As seen, when

the assembly

is installed and tightened, a side of the coupling blocks 48 and 46 for

engagement with surface 27 of

arm 26 (see solid line in Fig. 20) is initially chosen and the ball of plunger

90 corresponds with and

13

CA 02358154 2001-10-03

is disposed within a hole (either bore 112, 114, 116, or 118) of the index

bracket 50. After

installation and the indexer plate 50 and coupling block 48 are engaged, a

small gap 136, or

clearance, exists between block 48, with indexer plate disposed in contiguous

relation with the ball

spring plunger’s 90 collar. Also, in the preferred embodiment, axial

clearances 138, 140 remain

between the head of bolts 54 and 58 and the support plates 62 and 66,

respectively, after the bolts

are completely tightened (i.e., bottomed-out in bores 78) to the upgrade kit

40. These clearances

138, 140 permit the coupling blocks 46, 48 to easily rotate when adjusting the

coupling blocks,

discussed below.

To adjust the coupling blocks 46, 48 so that a different side engages surface

27 of lower

pivot arm 26, a torque is applied to bolt 54 in the clockwise direction, as

shown in Fig. 20. Since

this torque further tightens bolt 54 and bolt 54 has already bottomed-out in

bores 78, the applied

torque is transmitted to and causes the main shaft 42 and coupling blocks 46,

48 to rotate clockwise.

As torque is applied to the bolt 54, the ball 96 is compressed inward of

plunger 90 and forced out of

the hole of the indexer plate 50. When enough rotation is effected so that

ball 96 « f nds » the next

hole in the indexer plate 50, the ball again springs into engagement with the

indexer plate to prevent

further rotation of the adjuster blocks 46, 48. This process is repeated until

the desired coupling

block side (i.e., either side 84, 85, 86, or 87 (Fig. 9)) is in position to

engage surface 27 of arm 26,

shown as dotted lines Fig. 20.

The upgrade kit 40 of the present invention thus allows a quick and easy means

to adjust the

coupler of the Polaris~ snowmobile. As originally manufactured, the rider had

to first loosen the

central mounting bolt 126. Then the rider had to, either with his fingers or

with the aid of another

tool, rotate block 30 to the desired location, and then retighten the central

mounting bolt 126. The

rider had to then repeat these steps for the adjuster block on the opposite

slide rail. With the

14

CA 02358154 2001-10-03

upgrade kit 40 installed, however, the rider only needs to perform a single

step, which is to rotate

bolt 54 clockwise with a suitable tool until the desired side of coupling

blocks 46, 48 are in position.

Notably, no loosening of the system is required, and no further tightening is

required once the desire

coupling block side for engagement with surface 27 is in position. The ball

plunger’s 90

engagement with indexer plate 50 prevents further rotation of the adjuster

blocks without the need

to further tighten bolts 54 or 58. This allows the rider the ability to

quickly and easily adjust the

coupling of the suspension for varying terrain conditions. Furthermore, the

head of bolt 54 is

preferably sized to accommodate a conventional spark-plug wrench. Thus, the

rider, who typically

akeady carnes a spark-plug wrench when riding the snowmobile, need not bring

an additional tool

in order to make a coupling adjustment in the field.

Though not intended to be limiting, the dimensions of the components of

upgrade kit 5,

which are sized for the Polaris~ XTRA-10 snowmobile suspension, are the

following:

Table 1: Dimensions of upgrade kit 40 components.

Main Shaft 42 (Fig.dimension (inches)

6)

L1 8.468

L2 2.250

L3 1.000

D 1 0.500

D2 0.900

Coupling blocks 46, 48 (Figs. 7 and 8)

L4 1.656

L5 1.988

L6 0.750

L7 0.750

15

CA 02358154 2001-10-03

Lg 0.475

L9 0.344

L 10 1.000

Rl 0.750

R2 0.500

R3 0.375

R4 0.500

Indexer plate 50 (Fig. 14)

L11 3.741

D4 0.375

DS 0.265

D6 0.395

RS 1.000

Plate brackets 62, 66 (Fig. 14)

L12 3.741

D7 0.394

D8 0.375

Although the upgrade kit 40 with the above dimensions is intended for the

Polaris~ XTRA-

snowmobile, the dimensions of the components above can be modified to fit the

following

Polaris~ models: the STORM series (model years 1996-98); the STORM SE series

(year 1997); the

800 XCR series (model years 1999-2001); the XCR, XC, XCR SP, and XCR SE series

(model years

1996-2000), but excluding the 440 cc XCR, XC, and XC DELUXE models; the XC SP

(model

years 1999-2000); the ULTRA SPX and SPX SE series (model year 1997); the INDY

XLT series

(model year 1997); the INDY XCF (model year 1997-99); the INDY XLT Special

(model year

1998-99); the INDY 440 and 500 (model year 1996-1999); the INDY SUPER SPORT

series (model

year 1996-2000); the INDY TRAIL (model year 1996-99); and the INDY TRIUMPH

(model year

16

English

English